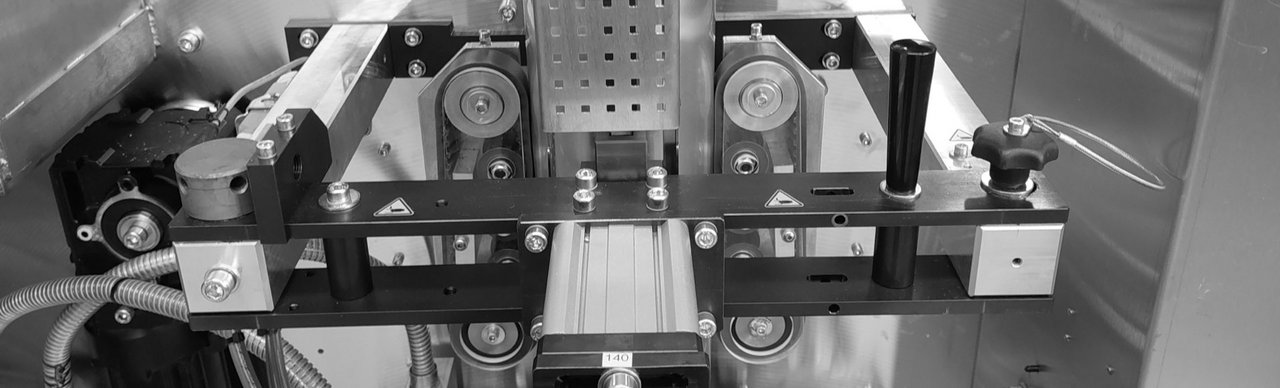

Vertical SKT V1 tubular bag filling system

Fully automatic filling machine for tubular bags with sealed edges

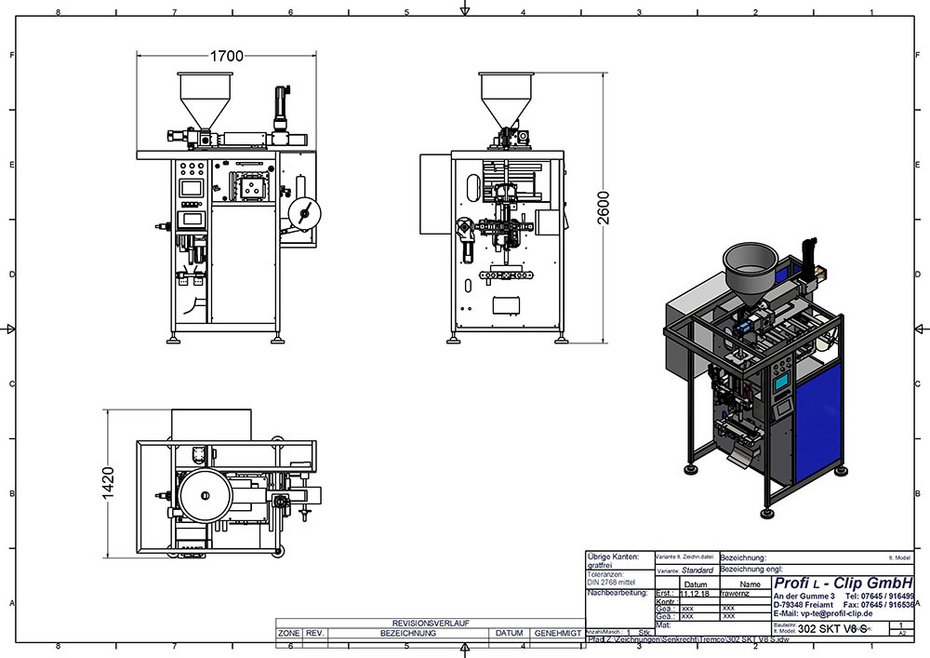

Technical data/dimensions

| Diameter range | 25 - 200 mm |

| Volume range | 50 ml - 6000 ml |

Filling material

- Adhesives

- Sealing materials

- Bulk material

Filling, filling product

- Tubular bags with sealed edges

- Tubular bags with aluminium clip closure

Benefit:

Machine in mirrored version, product alignment from left to right or right to left as selected

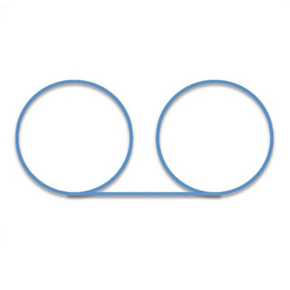

Product 1

Sealed edge tubular bag.

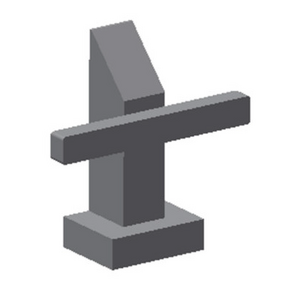

Product 2

Tubular bag closed with aluminum clip.

Modules and accessories for tubular bag fillings

Here you will find suitable modules for dosing, clipping, marking, inspecting and packing of tubular bag products.

Dosing, dosing modules

Hydraulic

dosing

- Suitable for products with high viscosity

- Benefit: electronic volume setting

Servo

dosing

- Suitable for products with low viscosity

- Benefit: servo drive controlled volume setting

Double

dosing

- Suitable for products with low to high viscosity

- Benefit: reciprocal filling

- 30% enhanced performance

Clips, clip closures, sealing

Wire clip

- Clip thickness:

2 – 2,7 mm

Sealing

- Bag sealing via heat sealing process

Marking and inspection modules

Printer

Suitable for:

- Thermal transfer printer

- Inkjet printer

Labelling machine

Suitable for:

- Tubular bags

- Lengthways and crossways labelling

Scales

Suitable for:

- Connection to scales with trend control

Handling: Manual packing

Packing table

- Adapted to customer requirements/available space

- Manual packing/tubular bags

Case sealer

- Semi-automatic sealing machine

- With outlet section

- For quick, straightforward packing

- Tailored to individual customer requirements